Requirements for the installation of the inlet ring of the backward centrifugal fan

The installation requirements for the inlet ring of the backward centrifugal fan include: installation position, installation angle and installation clearance, etc. Among them, the installation clearance has a certain influence on the performance of the fan.

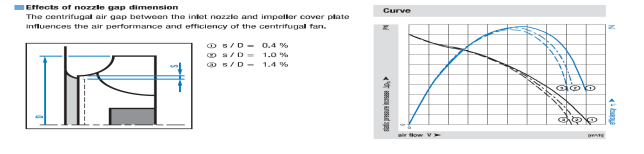

The gap between the centrifugal fan inlet ring and the impeller directly affects the air performance and efficiency of the fan.

Generally speaking, the installation gap between the inlet ring and the fan impeller should be as small as possible to reduce air leakage and energy loss. Smaller installation clearances can improve fan efficiency and wind pressure output. At the same time, smaller gaps also reduce turbulence and eddies in the wind flow, thereby reducing noise levels.

However, too small installation clearance may also cause friction between the fan impeller and the inlet ring, resulting in additional energy loss and noise generation, then affect the normal operation of the fan.

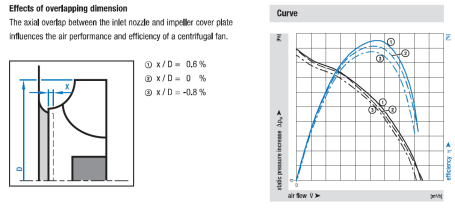

The axial overlap of the centrifugal fan inlet ring and the impeller also has a great influence on the air performance and efficiency of the fan. The best ratio of the length of the axial overlap between the inlet ring and the impeller to the diameter of the impeller is 0.6%.

Therefore, when installing the inlet ring of the backward centrifugal fan, the size of the inlet ring recommended in ebm's specification should generally be followed, as well as the suggestion for the axial overlap between the inlet ring and the impeller, so as to ensure that the fan can operate normally and obtain the best performance.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 简体中文

简体中文 whatsapp

whatsapp