Do you know the corrosion resistant class of the fan? Let's take a look today.

Usually, the corrosion resistant class of the fan is determined according to the corrosion resistance of its materials and coatings. Common fan corrosion resistant class include:

Ordinary corrosion resistance:

Certain anti-corrosion treatment is carried out on the surface of the fan, such as spraying anti-corrosion paint, etc., which can resist general corrosion to a certain extent.

High corrosion resistance:

The fan is made of materials with better corrosion resistance, such as stainless steel, galvanized steel, etc., which can resist strong corrosion.

Explosion-proof corrosion resistance:

Suitable for fans used in flammable and explosive environments, with explosion-proof and anti-corrosion functions.

Marine corrosion resistance:

It is suitable for fans used in marine environments and has the characteristics of seawater corrosion resistance.

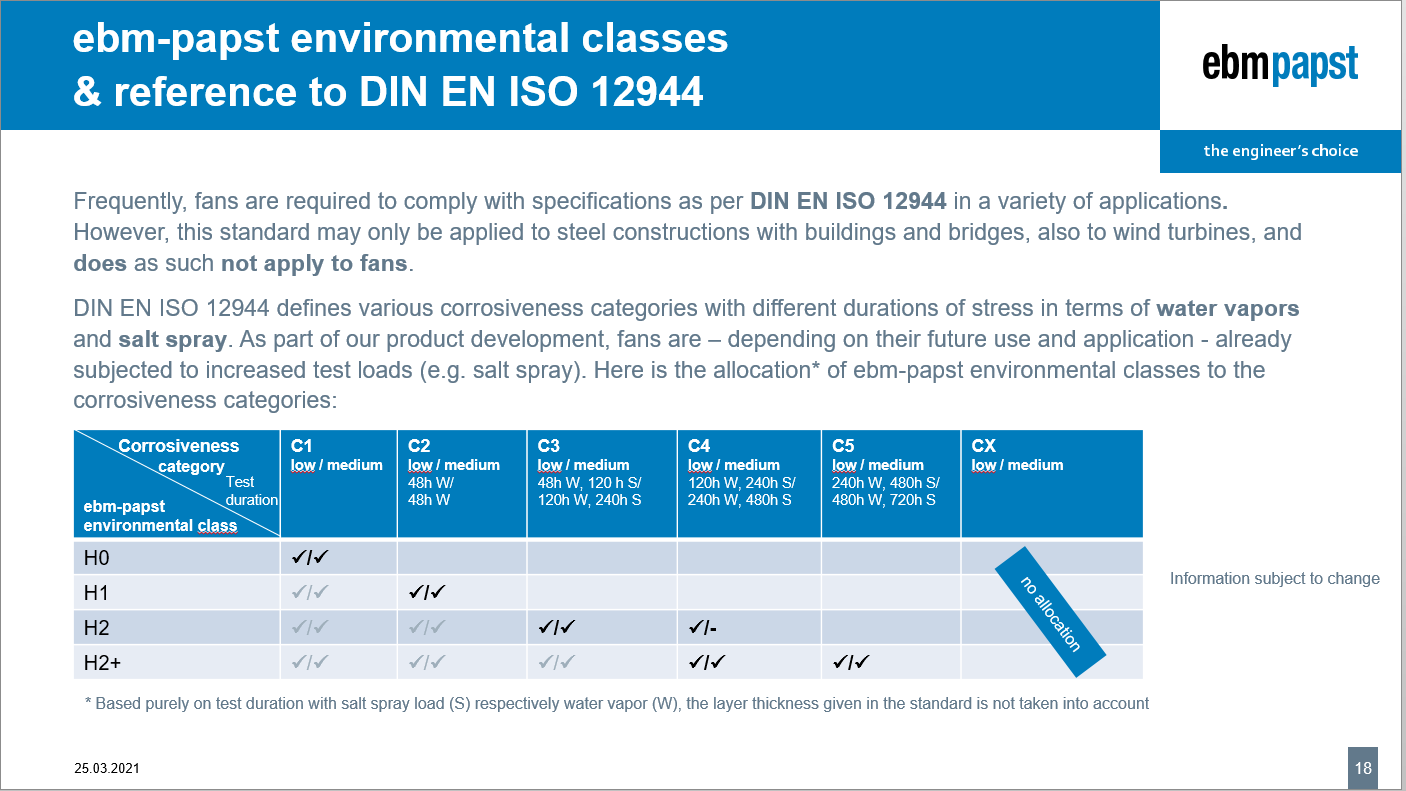

The corrosion resistance class varies according to different use environments and requirements. Specifically, it can be divided into C1, C2, C3, C4, C5, etc. The higher the level, the longer the salt spray test time can be tolerated, and you can choose the corrosion resistant fan according to the specific situation.

Our ebm-papst products also strictly distinguish the corrosion resistance class. In the specifications, you can see the words H1, H2, etc., which also have the following correspondence with the C1-C5 we mentioned earlier:

Follow us for getting more real stuff about fans.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 简体中文

简体中文 whatsapp

whatsapp